“But how do they make it look like there’s no seam?” Look, we’re not magicians (maybe 'metalagicians'...). But if we were, this would be our magic trick:

Abracadabra… *turns on wire EDM machine, waits 3 days, grinds then polishes*... magic the seams away!

See, no seams! (Don’t squint)

Today, I want to take you through the wonderful process that makes this incredibly cool magic trick possible: wire electrical discharge machining (EDM). And to better understand Wire EDM, we need to first look at EDM as a whole.

Alakazam!

Electrical Discharge Machining (EDM) without a wire

I know what you’re thinking. If it’s not magic, what is it? Electrical discharge machining, or as less of a mouthful, EDM, uses electrical energy rather than a mechanical force to remove material from a workpiece.

Okay, and how does it do that?... Magic!

No, please, wait. I’ll explain. There are two electrodes: the tool piece and the workpiece. When a (very, very) high voltage is set across these electrodes, and they get close enough, a spark forms. Each time the spark jumps across the electrodes, a part of the workpiece magically disappears. Taa-daa…

Sparks!

These sparks happen very quickly - up to millions of times per second - and the computer-controlled gap they jump across is known as the discharge gap. For the sake of controllability and other reasons that I’ll share soon, this process is not completed in open air but dielectric liquid.

As you’d expect, these sparks get very hot. In fact, the temperature at the point of discharge can reach between 8,000 and 12,000°C. That's hot enough to melt, vaporise and erode material away. But because the sparks are very localised, only a small amount of material is removed at once.

EDM dielectric liquid with tri-uses

The dielectric liquid plays a few roles.

- It rapidly cools and re-solidifies the molten material

- It flushes away the eroded particles

- It also acts as a semiconductor to help to stabilise the EDM process

Usually, the liquid of choice is deionised water or a specialised oil.

Dielectric liquid

As a rule of thumb, you’d choose deionised water if you’re working with wire EDM, complex geometries and high-precision parts. And then a specialised oil if you’re working with sinker EDM (see below) and hardened materials.

HAZard… or no?

Now, because the heating is extremely magic, sorry, localised, and the dielectric liquid helps to cool the workpiece very quickly, the heat-affected zone (HAZ) is small. And, usually, it doesn’t impact material heat treatments.

But metals and rapid heating and cooling don’t always go hand in hand. So, albeit small and not to the same extent as it is with welding, the HAZ can pose potential risks. Besides, it’s still fun to understand the bigger picture.

For my next trick... a crash course in HAZ.

Welding HAZ

Rapid heating and cooling, in short, induce thermal stress. Thermal stress, in turn, alters a metal's microstructure, which then, in turn, alters its properties. For example, in steels, martensite (a hard and brittle phase of the microstructure) can form near the surface. This is because rapid thermal cycling doesn’t provide the necessary time for carbon to diffuse out - and it stays trapped. As a result, tensile stresses accumulate and microcracks can form, potentially causing material failure (waaaayy sooner than it should).

Again, remember the HAZ is smaller in EDM than in welding. But the principle is the same.

Pick an EDM, any EDM

Before we look at wire EDM, I'd like to share some other types. Conventional EDM, as we’ve just seen, is great for etching away at material - and not so good for processes like cutting or drilling.

Each type of EDM follows the same process, but the shape of the tool piece electrode changes so it can magic away material differently.

Sinker EDM (or Die-Sinking EDM)

Here, you use a shaped electrode, after submerging it in a dielectric liquid, to form cavities or complex shapes. Like this:

Notice the shaped electrode

Hole Drilling EDM

Here, you use a tubular electrode to drill small, precise holes into a workpiece. This is particularly common for drilling small holes into turbine blades to create intricate cooling channels.

See the tiny holes?

Now time for the all almighty. Don’t try this at home.

Wire EDM: Behind the seams

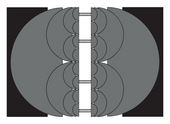

Wire electrical discharge machining (WEDM), AKA wire-cut EDM, follows a very similar process. But rather than etching like conventional EDM, WEDM slices. (Not a person in a box either)

Wire EDM uses a thin, continuously fed metallic wire to cut a workpiece into intricate shapes. The wire actually looks a lot like cheese wire (and before you think about it, no, you probably shouldn’t try to ‘wire EDM’ your cheese at home). Here, the metallic wire is the electrode, and it erodes alongside the workpiece - hence why it’s continuously fed. To create different top and bottom profiles of the workpiece, you can also angle the wire to create inclines. (FYI: There’s a great diagram here)

Like the other types of EDMs, both pieces must be conductive for the process to work. Often, machine shops use brass or (stratified) copper as their wire because of their high conductivity. But tungsten, molybdenum and steel-core wires are used too.

Typically, a wire electrode has a diameter between 0.1 - 0.3mm, but depending on what they’re cutting and the application of the end product, you can use smaller or larger diameters.

Here’s a great walkthrough of EDM courtesy of Steve Mould

Hair-splitting accuracy

The real magic of wire EDM comes in the fact you can cut all metals. So, for all those hard-to-work materials that traditional cutting tools can’t cut or shape, wire EDM can.

This poses the question: can they cut well? Or will the cut look like a failed magician's frayed and burnt rope? The answer is a resounding yes... in favour of well-cut.

Wire EDM machines can maintain a wire positional accuracy of ~0.0001mm and cut parts to a tolerance of 0.002mm, although some specialist machines can go even further. This is like taking a sheet of paper and slicing its thickness 6 times. Or a hair 5 times.

Hocus-pocus! Oh, wait…

Advantages of Wire EDM

Wire EDM is popular for a long list of good reasons. Let’s look at what they are.

- Accuracy and precision. As we saw, wire EDM has hair-splitting tolerances, making it great for lots of important applications.

- Low workpiece distortion. There’s no bulk heating, tearing or fracturing. In fact, there’s no physical impact at all. So, comparably, the internal stresses are very low (even with HAZ).

- Complex shapes. You have unlimited 2D geometries. Wire EDM is infinitely manoeuvrable and cannot misapply force. Currently, 3D geometries are limited, but thanks to 5-axis wire EDM, they’re quickly improving.

- Works with all metals. You can work with any conductive material. Because wire EDM applies no force, hardness and brittleness have no impact on the process rate.

- Process efficiency. Because of the accuracy and no applied force, workpieces don’t have burrs or distortion, meaning they need fewer processes after.

- Safe operation. Even with high voltages, wire EDM is still very safe and predictable. (EDM machines often work the night shift because they're a bit slow, too).

- No fixtures. You don't need specific fixtures to cut and process the workpieces. And they're usually pretty expensive.

- Weak material capabilities. Not only is wire EDM good for extremely hard materials, but weaker ones, too. Because no force is applied, materials that are usually too fragile for traditional machining can be cut and shaped with ease.

- Small production runs. Thanks to the nature of the process, WEDM can accommodate small production runs.

But what about the flip side?

Disadvantages of Wire EDM

Of course, nothing is perfect. Wire EDM has its disadvantages, too. So, alakazam, here they are:

- Sharp corners. Because the wire has a tiny diameter (~0.1 - 0.3mm), it simply can’t produce sharp corners. Of course, wire size varies, so the minimum piece radius does too. But sharp, sharp corners that traditional cutting can provide, wire EDM cannot.

- Conductive materials only. It's no problemo if you’re only cutting metals. But it does cross out composites, plastics and any non-conductive coated materials.

- EDM machines are expensive up-front, maintenance isn’t always cheap, and you also have to pay for the consumables (wire and dielectric liquid).

- It’s ssllloooowww. Compared to many of the traditional cutting machines, wire EDM is slow.

- HAZ. Albeit localised, the workpiece is still heated to thousands of degrees. This rapid thermal cycling can have a knock-on effect on the material properties.

- Oxide layers. On some materials, like aluminium, oxide layers can form. This may require secondary cleaning or additional treatments before the workpiece can be ticked off.

- Tubes are a no-go. Tubing or hollow shapes are harder to clamp, meaning they're then harder to cut and cool. Wire EDM is far better for solid shapes.

- Surface roughness. Yes, it’s accurate. Yes, it looks like magic. But wire EDM cutting can leave some surface roughness. However, with extra passes or additional measures, it also cannot.

Wire EDM Applications

Wire EDM can cut ferrous and non-ferrous metals, long and heavy pieces, and also small and intricate ones. So, it's a very common method of cutting and shaping metal. Several industries use it, and the main ones are…

Automotive

Because the wire doesn’t make contact, it doesn’t need to be stronger than the workpiece (like it would be in other cutting methods). So, wire EDM is great for hard materials, which can then be used to make tools and dies. The same tools and dies that make bumpers, dashboards and car doors.

Aerospace

Thanks to its accuracy, wire EDM is great for producing parts with tight tolerances. And as we know, hardness also has no impact on the process, so it’s often the go-to machining process for aerospace part manufacturers. The most common parts include engine internals and turbine blades.

Medical

Again, thanks to the hair-splitting levels of accuracy and ability to shape tight geometries, wire EDM is also used in medical fields, particularly optometry and dentistry. Since the wire diameter determines the cut size, and wire diameters are usually very small, WEDM machines can produce tiny features to parts like dental implants and syringe components. All without distorting or endangering the part’s structural integrity.

Stress-busting

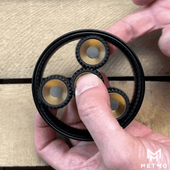

And maybe the most important of them all… “stress-busting”. Wire EDM helps create magic-looking, finger-aching, curiosity-building fidget toys. On the count of three, say the magic words…

1… 2… 3…

“MetMo Cube”

*Puff of smoke*

The MetMo Cube that’s now on a wave-order regime thanks to its popularity

Love, desire and the creation of metal-cutting cheese wire

So, if you’re still here and want to know even more about Wire EDM, whisper the magic words once more. Actually, no, not this time.

It all started with the scientist, theologian, chemist, philosopher, political theorist (and unfortunately not magician) who discovered oxygen: Joseph Priestley. Not only was his time management impressive, but so were his recorded observations. Because in 1770, he noted that electrical charges could remove material from electrodes.

Later, in 1881, Auguste de Méritens built on these observations and began to transfer material using electric discharges in arc welding.

However, it wasn’t until the latter end of World War II, in 1943, that two Soviet researchers discovered how to erode hard-to-work materials like tungsten in a precise and repeatable way. It was husband and wife, Boris and Natalya Lazarenko, who brought EDM to life.

Around a similar time, in the US, Jack Beaver, Harold Stark and Victor Harding developed a spark-erosion machine to remove broken bolts and taps from aluminium castings. This was completely independent and a complete coincidence.

But the US machine could arc at a rate of 60 discharges per second (vs the millions now). Later developments used vacuum tube pulse generation and got several thousand arcs per second, making it a still slow but more viable route of machining metal.

Wire EDM, as we know it now, came in 1967. Again, from the Soviet Union. It was a sort of an ‘arc bandsaw’ or a “cheese wire” that would cut or slice complex 2D shapes.

Progress continues. And in the 80s, EDM discharges became faster and faster. In fact, they could now erode material at speeds of 64mm2/min. Granted, for easy-to-work materials, it wasn’t too popular (yet), but for hard-to-work materials like hardened steel and titanium, the result was worth the wait (and the most cost-effective option).

Since then, EDM has continued to develop into what it is today. And you can now have 5-axis wire EDM machines that handle complex operations across a range of industries.

The final cut

Voilà! Way too many tragic magic puns later, you’re now an expert on EDM. You know what types there are, how they work, what they do, where they’re used and where they came from.

You might have even found a new way to cut your cheese.

But, anyway, you’ve seen beyond the seams, hopefully, to realise the seams were there all along…

Again, if you’d like to see what we can do with wire EDM, the MetMo cube is linked here. Or to learn more about it, read this article.

Share:

Time to Inspect(y)or Gadget...

Pocket Driver: From Silver to Gold