MetMo

Multi Drive Black Steel

Multi Drive Black Steel

Couldn't load pickup availability

Multi Drive Set with black hard anodised aluminium and stainless steel Multi Drive.

1 x MetMo Multi Drive Handle | Black Steel

1 x 4mm Adapter

1 x Blade Mount

1 x Scribe

1 x Flat File

1 x Grease Lead

2 x Micro Bits

5 x 10A Blades

6 x 2B Hi-polymer graphite leads

1 x Allen Key

Materials

Materials

- Hard anodised aluminium (7055-T77 Aerospace grade)

- Ground Bearings (Stainless Steel)

- Stainless Steel (420C Grade)

- Hight Tensile Grub Screw (Class 14.9 bolts)

Shipping & Returns

Shipping & Returns

Available to ship immediately.

30 day returns policy.

Dimensions

Dimensions

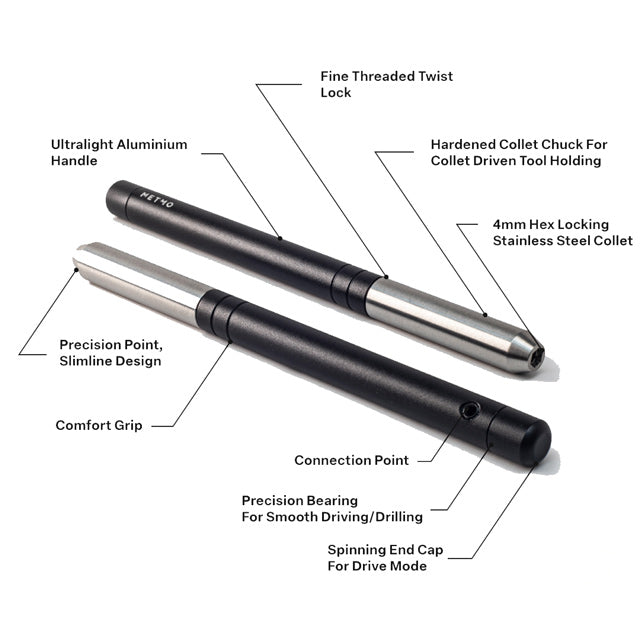

Size: 10mm (0.39") x 10mm (0.39") x 138mm (5.4")

Weight: 29.2g (1.0 Oz)

Bit Size: 5/32 (4mm) hex drive bits

Technical Details

Technical Details

Finish: Hard anodised Black.

Maximum Torque: 2.2 Nm (1.6 lbf)

Bit Size: 5/32 (4mm) hex drive bits

Magnetic Socket: Yes

What's in the box

What's in the box

1 x MetMo Multi Drive Handle

1 x 4mm Adapter

1 x Blade Mount

1 x Scribe

1 x Flat File

1 x Grease Lead

2 x Micro Bits

5 x 10A Blades

6 x 2B Hi-polymer graphite leads

1 x Allen Key

A Classic Tool Reinvented For The Modern Era

A new kind of multi-tool inspired by engineers' marking out tools, Multi Drive uses precision engineering to create a versatile, hardwearing and useful tool that's in its element in the office, shed, or workshop.

Built like tools from a bygone era to be useful in many situations and engineered to last generations.

Why Have We Created MetMo Multi Drive?

We started with a simple idea; we wanted to make a really great craft knife. Having used pretty much every kind of scalpel knife and weird ergo handle over the years, we knew we could bring some MetMo magic to a tool every maker needs in their arsenal. But this hunt for the perfect knife quickly made us realise something much more interesting.

What Can It Do?

What can't it do?

A multi-tool that emphasises the tool. In short, this is a: Knife, Pencil, Scribe, Drill, File and Micro Driver. And it does them all really damn well.

Perfect for handling everything from computer builds, model making and finishing up 3D prints, through to marking out, sketching and etching. Each attachment does its job quickly and perfectly so you can create, fix and tinker to your heart's content.

A Class Of Its Own

Multi Drive is in a class of its own, letting you carry a small tool set that can be used on nearly anything you want to turn your hand to. Designed to feel familiar like a pencil, working with it feels totally natural and enjoyable.

Who's It For?

Made for designers, engineers, thinkers, and anyone who wants to just take a moment, get creative or play around. MetMo Multi Drive is a versatile tool that can adapt to any situation. Made by creative people that wanted something better while working on smaller projects at our desks (where all big projects start!). After all, why should tools only be used in the workshop?

A Powerful Tool And The Perfect Desk Companion

Is that a workshop in your pocket or are you just happy to see me? Carry a small arsenal of capable tools in your pocket. The slimline and modular design of each part lets you carry the workshop classics wherever you go, so you can set up and start creating anywhere.

Chomping At Your Bits

With a simple twist, the hex collet clamps down onto the shaft, creating a seamless tool for enacting all kinds of crafty mayhem.

The collet system is fast- real fast! Like a wheel change by an F1 team, you can swap between attachments in seconds without the need for chuck keys, wobbly spring plungers or magnets. Just twist to release or clamp, so you don’t have to waste time fiddling around with the tool, and get back to what you're working on.

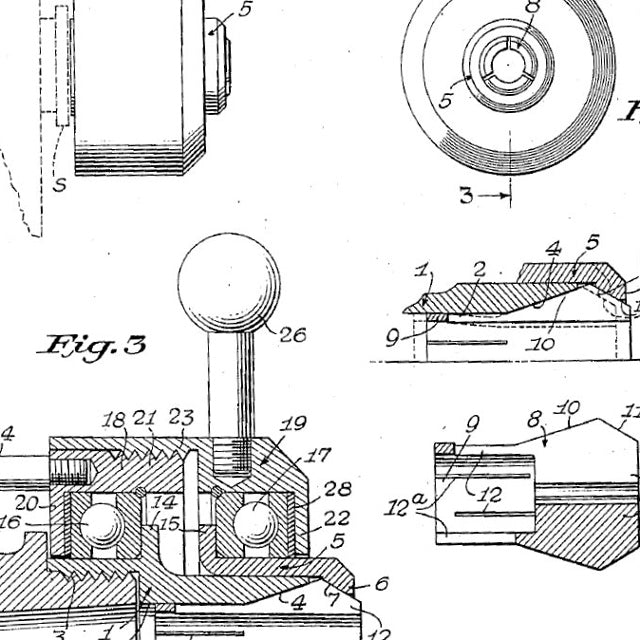

Collet History

Utilising a machine collet system pioneered 150 years ago and perfected by engineers in the 70’s for holding high speed machine tools perfectly centralised and stable, we've brought the past to the modern age.

Originally they were developed by watch makers to be able to hold and machine the tiny precision mechanisms needed inside of watches!

Similar mechanisms are used on other powered micro tools, but when you get down to it they're nothing like the quality and precision of the originals. We have miniaturised and modernised the materials, taking inspiration from the collets used in some of our marking out tools that are over 40 years old and still work flawlessly.

"Why?" I hear you ask… Collets give an unbelievable level of precision grip in Multi Drive, which means that it holds graphite, drive bits, or anything totally rock solid, with no wobbling or play between the parts, connecting you with the business end of the tool like it was forged in one piece unlike any other multi tool.

Get The Hell Out Of Here Plastic!

Do more with less. Have one set of tools on your desk that can be used for a multitude of things. Let’s face it, space is at a premium on any desk or workbench and Multi Drive makes the most of it by combining 6 tools into one neat area.

Take It Easy On The Hands

We were tired of using tools that after 10 minutes of applying pressure leave you with knife handle imprints in your fingers. So we made everything round, smooth and comfortable to hold. Mankind did it for pens, so why can’t MetMo-kind do it for our tools?

A simple yet comfortable design gives the perfect control for any hand held crafting.

In A Class Of Its Own

Multi Drive forges a new class of tool, bringing precision engineering to the world of craft tools. With its compact design and quick tool changes, Multi Drive has everything you need to start creating, wherever you are. A true Multi-tool, saving you space in your everyday carry.

Why This Design?

Modern tools are made to a price, and most use cheap plastics and components that are designed to break after a limited number of uses. We wanted to make something with a full metal construction to bring engineering grade quality production into the world of craft tools, to create something that would stand the test of time, putting fun and precision back into the task at hand.

The One To Rule Them All

A single handle you can use over and over, on whatever you're working on. More than a multi-tool, this is a versatile collet driver unlike anything else. When you carry a Multi Drive, you're carrying 6 tools in one. Carry less, do more.

Sits In a Pocket

Neatly sits in your pocket, ready for action as a pencil or driver, (though not advised with the knife unless you like holes in your pockets…). So, why not adorn your top pocket with some next level equipment and be ready for when a colleague asks “does anyone have a 0.8 Pentalobe?”

Stainless Steel Collet

Conventional collets just weren’t cutting it; we tried using some early on and the centres were all over the place. Ours ensure the lead, drive bit or knife blade sits perfectly in the centre every time. How can you be precise when you're working if the very tool you're using is wonky?

Perfectly Balanced

Designed to be more than a screwdriver. We've removed the perfect amount of metal at both ends so it has the balance of a high-end executive pen, allowing you to simply enjoy the process of what you're working on.

Silky Smooth Bearings

Chewing on the end of your pencil will be a thing of the past! With the satisfyingly smooth motion of the end cap, Multi Drive is a joy to fiddle with and is hard to put down once you pick it up.

Precision Micro Screwdriver

A fine, slimmed down tip allows for full visibility of what you are working on. Ideal for those tiny screws where you need to see what you are doing and allowing light to reach your work area, Multi Drive makes life that much easier.

Slimline Design

Designed for precision. The slimline and long profile lets you get into tight spaces, so you don’t end up having to jam your hand inside of a machine to reach a tiny screw. We've all been there when it rattles off inside something, then that feeling of "where the hell did that just go” sinks in…

Hexagon High Torque Lock

A uniquely engineered hexagon locking mechanism seamlessly turns the handle into a driver that won't slip or flex, letting you put as much force as you need into screws without damaging the driver.

Use With Any Drive Bit

The driver works with any standardised 4mm (5/32) micro drive bits made by all of the big tool manufacturers, so you can use the Multi Drive with thousands of bits and specialised screw heads to meet your exact needs, giving you more from the driver.

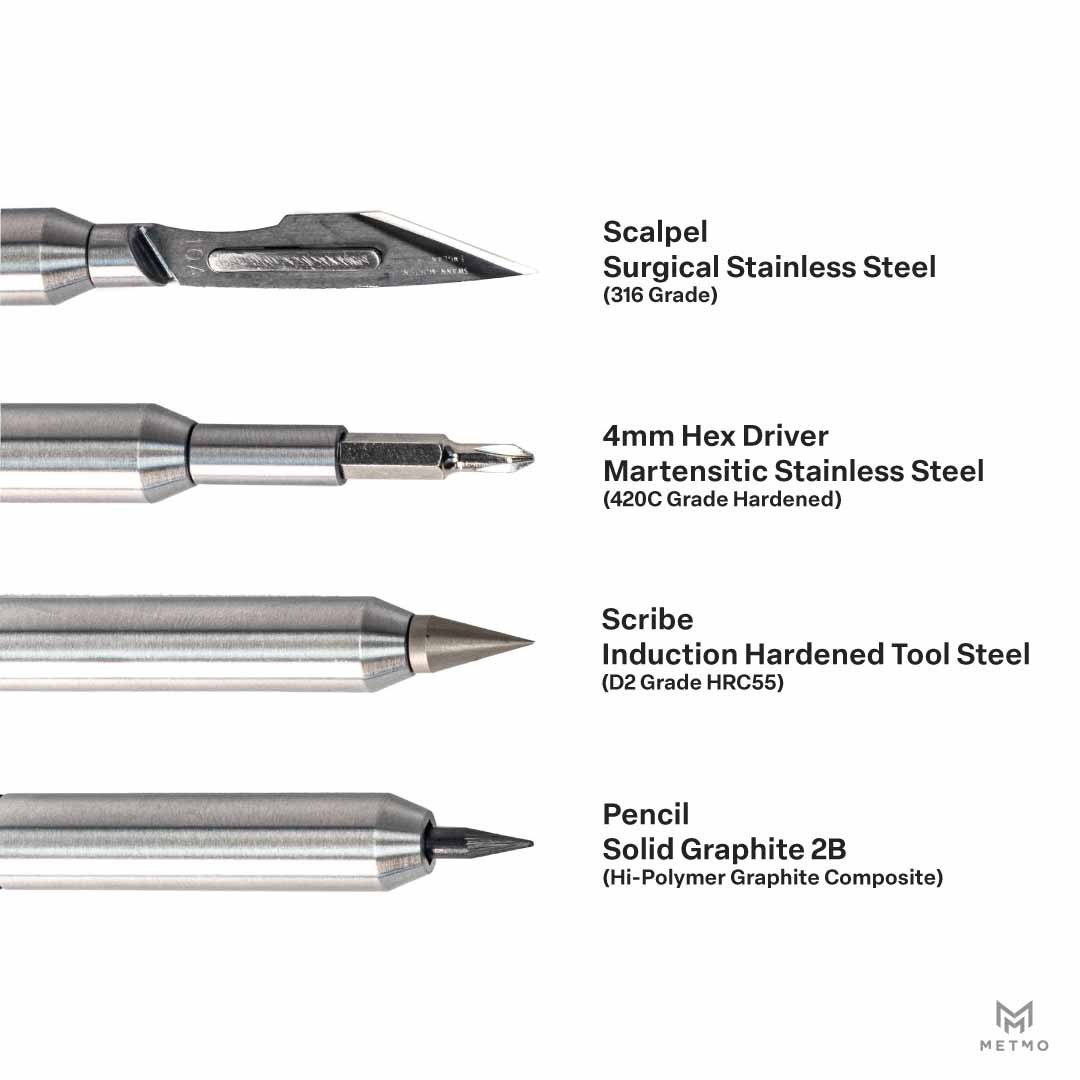

Drill With Precision

Drill all the way down to 0.5mm with ultimate control, venturing where powered drills fear to tread. Micro drill bits (or pin drills as they're sometimes called) are perfect for clearing out holes on Airfix models or mounting your Black Templars sword to be painted.

Control Every Cut

Designed to give you full control over the blade, like a modern day Musashi. The tapered tip that flows into the blade lets you get up close and personal with your work piece and the round handle allows you to easily rotate the blade and access the more intimate areas of dragons.

Slice With Surgical Precision

Works with all standardised stainless-steel scalpel blades, so you can use a wide variety of tried and tested blades that are easy to get hold of. Trusted by the professionals and ideal for fine work with paper and plastics or finishing 3D prints, these are versatile tools that get the job done. Watch the fingers though, these are purposely designed to cut you with little to no effort! (The best surgical blades in the world are made just 30 miles away from MetMo HQ!)

An Abrasive Solution

Protect your hand from unfinished needle files. Load them into the collet and you're up and filing fast, giving you more comfort and control whilst being able to put more power through the file. This lets you work more effectively, saving both time and your hands.

The Noble Scribe

Dating back to Mesopotamia and clay tablets, the humble scribe has stuck with us and is still one of the most precise ways to mark out metal and plastics. Our scribe has a hardened tip, designed to stay sharp and leave a permanent mark on any hard surface. Once loaded into Multi Drive it allows you to work like you would using a pencil, giving you more control in the high stakes world of metal marking or the even higher stakes game of hand-etching your name into your other tools!

Lock And Lead

More versatile than conventional graphite, a 3mm Hi-Polymer Graphite rod is perfect for making notes and doodling, but also marking out and scribbling on wood. Being thicker than standard means it lasts much longer and withstands more punishment while working.

Not limited by hardness, Multi Drive can accept any graphite from H6 to B6! Life is hard enough without having to worry about what lead you should be using in your pencil.

Rod Safety

The frustration of broken pencil leads will be a thing of the past. Housing the graphite rods in 1.5mm of metal protects it from impact, saving you time in sharpening pencil wood to find the ghost of a lead that was once living within.

Built To Last A Lifetime

Like all things MetMo, Multi Drive is made to last generations using some serious metal that will take more punishment than any pencil or driver ever should. A mechanism that has been around for over two centuries combined with an unrelenting drive for superior materials selection means that no other mechanical pencil or micro driver is built quite like this. Designed to last like the tools of old, future proofed and backwards compatible, it’s not going to let you or future generations down when you need it.

But what about the Hardware?

Load up Multi Drive with the specially designed tips that pack a punch. Built to perform, each one is tailored to the specific job, so there are no compromises like you get with a traditional multi tool.

Safety Tests

With only a few moving parts, we took the approach that the main point of failure would be the collet slipping or disengaging in drive mode. We came up with some pretty unconventional ways of testing each design iteration.

We applied a heavy weight to a 3mm rod that attached to the hand tightened collet and acted as a good test for how well our collet design was going to hold before it started to slip.

It was somewhat tiring on the arms, but the Multi Drive didn't slip once under these conditions and we took it up to 3.7kg (with a shock load too), before we decided this was far beyond what it will encounter in the real world and gave it a big tick ✅

Talking The Torque

Like all of our drivers, we have put Multi Drive through torque testing. For the Micro Driver attachment we decided that it didn't need to withstand any extreme loads, since that would break, strip or deform any fragile micro screw.

We still tested it well beyond what a micro screw would need, pushing it to 2.2Nm (a wood screw typically takes 1.5Nm of force to drive into wood!). We figured if what you're working on needs more than that, it's time to crack out Pocket Driver!

We stopped at 2.2Nm mainly because it was impossible to apply more force at that point without injury, even with a modified lever attached to the handle.

So, What's The Deal, Why Does It Cost £119?

Here at MetMo we are not your usual 'buy it cheap, sell it high' kind of company. We think 'what would make this truly great?' then uncompromisingly work towards that goal. This pursuit means we take a totally different route to make products.

But what does that mean? Well that means we machine every part on state of the art CNC machines, normally used for slow precision engineering, not designed for mass manufacture. It means that we use the best materials and surface finishes we can find and not the cheapest and fastest to make, and this all costs more to do.

We do all this to make sure we are making products the way our forefathers used to, totally over engineered to last generations, because they would not be happy with something that broke after a few years and neither are we!

Making of the Driver Prototype

Sit back, relax, and enjoy this video of the making of the MetMo Multi Drive prototype from scratch with our master metal worker, Geoff.

We go through every milling, drilling, turning, broaching and tapping process to make a Multi Drive from raw billets of metal, so you can see the amount of work involved in making each Multi Drive. Although this one off was made by hand using manual machinery, the production ones will use industrial CNC machinery.